CHALLENGES AND STRENGTHS

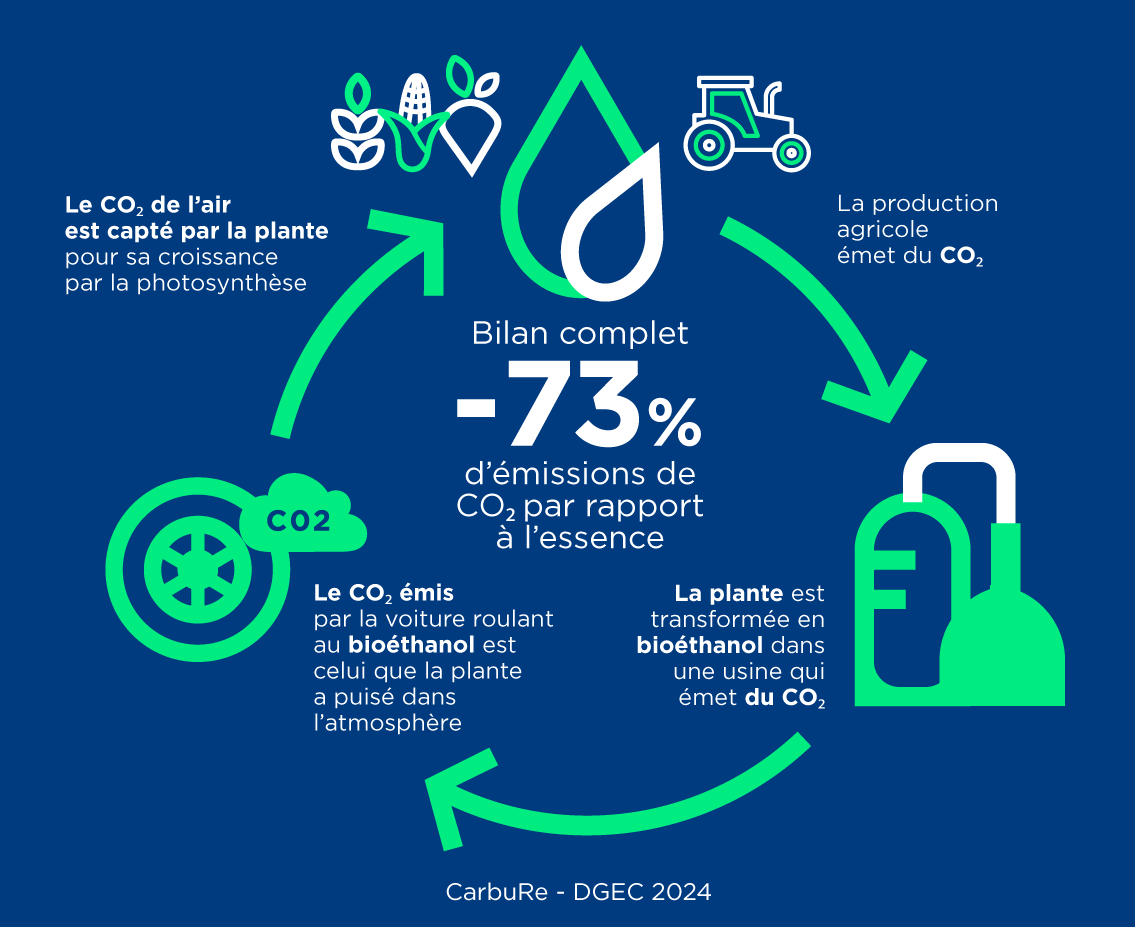

Bioethanol, a fuel that reduces CO₂ emissions by more than 73%

Bioethanol is produced from sugar beets and cereals (wheat, corn). It is a renewable energy source. It follows a virtuous cycle.

The CO₂ emitted during its combustion comes from the atmosphere, as it was captured by the plants during their growth.

According to the DGEC’s CarbuRe website, which tracks biofuel consumption in France, the bioethanol blended in France in 2023 reduces net greenhouse gas emissions by more than 73% on average*.

This corresponds to over 2 million tonnes of CO₂ saved each year, equivalent to one million CO₂-free vehicles***.

France, the leading European producer

France produces approximately 11 to 12 million hectoliters of bioethanol each year, representing 20% of European production. It is the leading European producer, ahead of Germany.

France exports a portion of its production to other European countries.

A local and sustainable supply

French bioethanol plants rely on short supply chains to source their plant-based raw materials.

The majority of bioethanol consumed in France is produced domestically, strengthening national energy autonomy while supporting local agriculture (beets, wheat, corn, and the waste and residues from their processing for animal feed).

State-of-the-art industrial infrastructure

The bioethanol sector in France has invested over one billion euros in the construction of five state-of-the-art industrial plants, which are among the most efficient in the world.

The majority of sites incorporate more environmentally friendly technologies, including:

• Capture of CO₂ from alcoholic fermentation (one tonne of CO₂ per tonne of alcohol) to reduce emissions.

• Methanization of effluents to produce energy.

• Production of steam using geothermal energy, biomass, or even household waste.

Full valorization of raw materials

Bioethanol plants do not produce alcohol only. Elles génèrent des coproduits essentiels pour d’autres secteurs :

Animal feed: cereal distillers’ grains, rich in protein, and beet pulp, rich in cellulose, replace imported plant proteins, particularly imported soybean meal.

Food industry: the CO₂ emitted during fermentation is captured, in some plants, for the production of carbonated beverages.

A choice for the future

Alongside electrification, bioethanol is establishing itself as a key player in the energy transition and in reducing greenhouse gas emissions.

With local production, modern infrastructure, and full resource valorization, it offers a concrete and sustainable solution to combine mobility with environmental protection. Il participe à la décarbonation des véhicules légers.

Superethanol-E85, a 100% renewable fuel with no fossil gasoline, is currently under development.

*French General Directorate for Energy and Climate (DGEC)

**in CO₂ equivalent

*for vehicles emitting 2 tonnes per year (gasoline vehicle consuming 7L/100 km over 13,000 km)